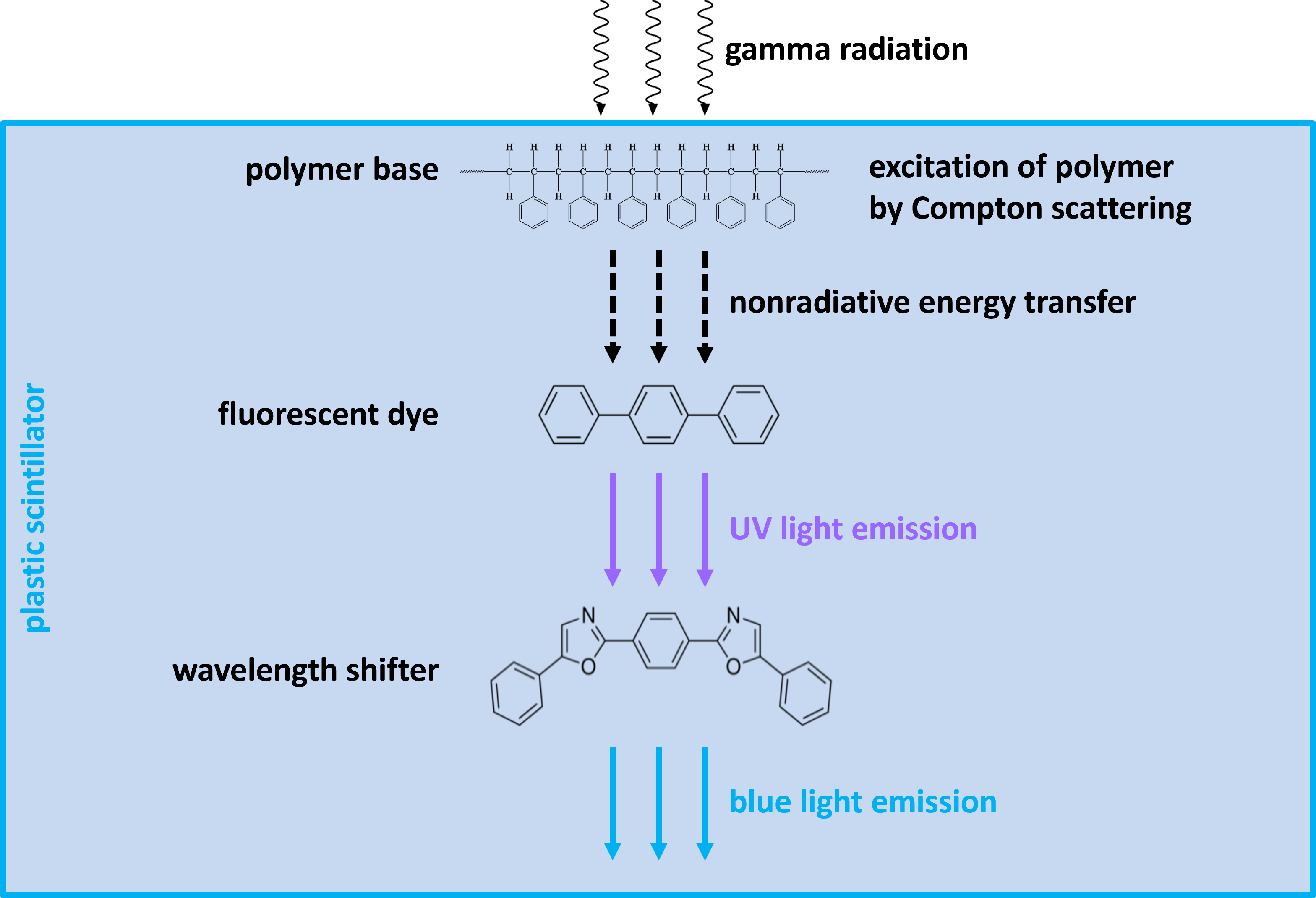

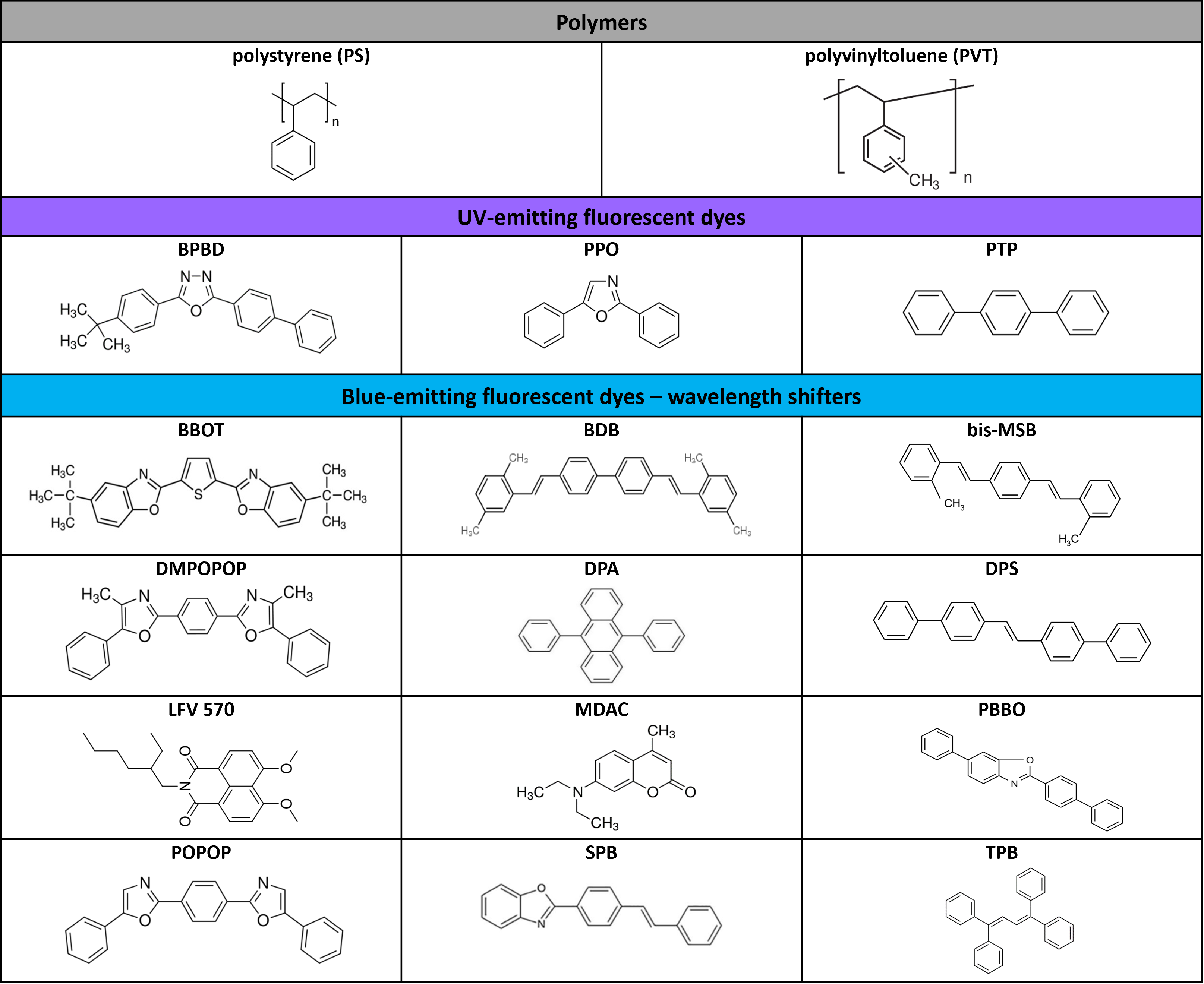

Plastic scintillator is an optical material converting ionizing radiation into light. It consist of one or two fluorescent dyes dissolved in polymeric base. Polystyrene (PS) and polyvinyltoluene (PVT) are mainly used as polymer base of plastic scintillators due to their transparency to visible and part of ultraviolet (UV) light. From chemical point of view PS and PVT contain phenyl units in their polymer chain and this molecular structure allows to be excited by radiation interacting with the plastic scintillator. These polymers have also amorphous structure – polymer chains are randomly positioned in volume of plastic scintillator and as a consequence plastic scintillator is transparent to it own emitted light. Large transparency of plastic scintillator material allows the construction of time-of-flight PET scanners with long field-of-view.

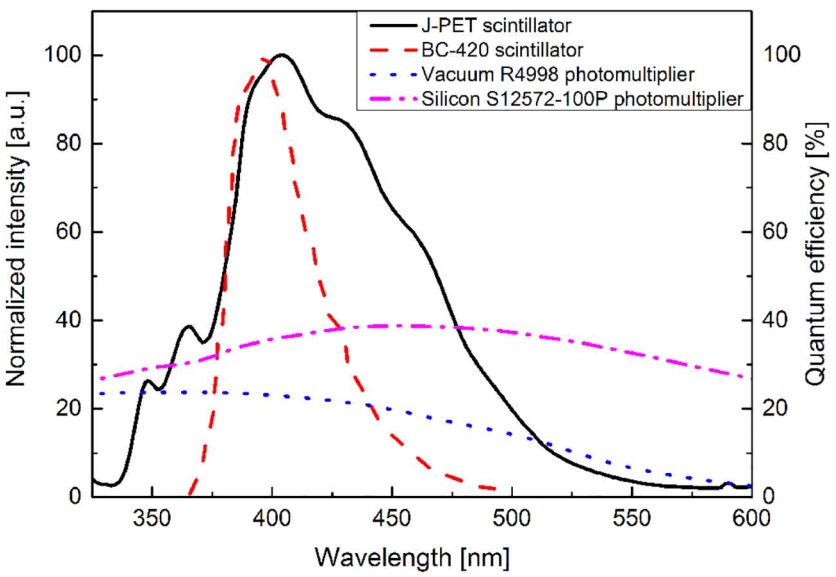

Left: Energy flow in plastic scintillators excited by gamma radiation. Compton scattering is main mechanism in J-PET scanner. Gamma quanta with energy 511 keV eject electrons which excite polymer. High concentration of fluorescent dye allows nonradiative energy transfer from the polymer to the primary fluorescent dye which emits UV light via fluorescence. Low concentration of WLS shifts emission spectrum of the scintillator also via fluorescence. Right: Emission spectra of the J-PET (solid line) and BC-420 (dashed line) plastic scintillators superimposed on the quantum efficiency dependence on photons wavelength for typical PMT with bialcali window (dotted line) and SiPM for PET applications light detectors (dashed-dotted line).

During manufacturing of plastic scintillators usually two fluorescent substances are dissolved in liquid monomer (styrene or vinyltoluene) and polymerized by free radical bulk polymerization to obtain solid polystyrene or polyvinyltoluene scintillator. First fluorescent dye (few percent concentration in polymer) absorbs energy from the excited polymer and emits UV light around 350 nm with high efficiency. Second fluorescent dye called wavelength shifter (WLS) absorbs UV light and emits blue light in range from 400 to 450 nm. WLS is added to plastic scintillators in small concentration about a few hundredths of percent to shift emission spectra to region where photomultiplier tube (PMT) and silicon photomultiplier (SiPM) light detectors have the highest quantum efficiency of converting light into electric signal.

Molecular structures of chemical components commonly used to manufacture plastic scintillators. PS and PVT polymers are used to produce commercial plastic scintillators but in research and development projects many other types of polymers are utilized.

Additionally, shifting emission spectra of plastic scintillator from UV to visible light increases transparency of scintillator because blue light is less attenuated in PS or PVT matrix. Both fluorescent additions have almost 100 percent fluorescent quantum efficiency and very short decay time in range from 1 to 2 nanoseconds. Efficient and fast conversion of gamma radiation into blue light is possible due to mentioned properties of fluorescent dyes. As a result of the factors described above, plastic scintillators emit about 10 000 blue photons per MeV of absorbed radiation energy with short pulse duration in range of few nanoseconds. Fast timing of signals are foundation of time-of-flight PET scanners, for example J-PET scanner based on fast plastic scintillators.

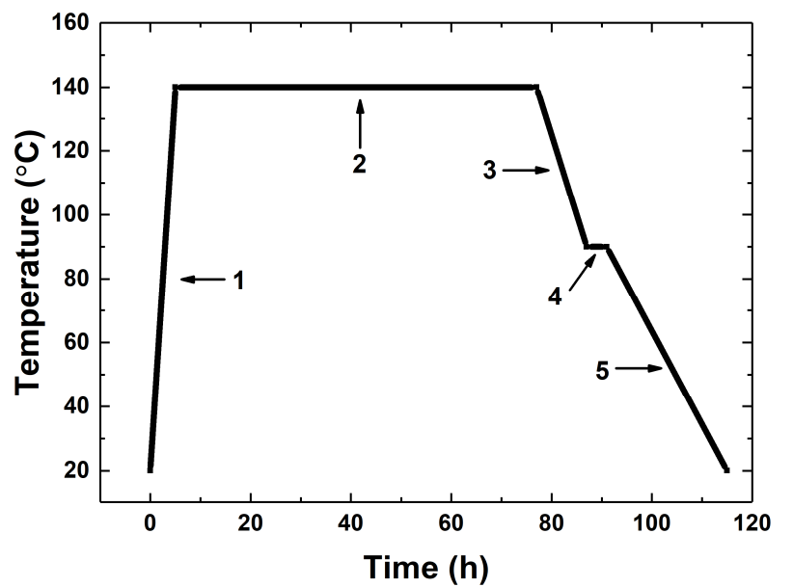

Left: The bulk polymerization of the fluorescent compounds dissolved in liquid monomer is conducted in the electric furnace with hot air circulation. Right: Heating cycle (1 and 2) has duration of a few days and contains slow cooling (3 and 5) and annealing (4) steps to prevent polymer from cracking.

Plastic scintillators have very high transparency for visible light. Technical attenuation length (TAL) describes light signal attenuation along scintillator strip and determines maximum useful length of scintillators in J-PET detector. High TAL value increases time resolution of the total-body J-PET scanner because more light reaches silicon photomultipliers attached at both ends of the plastic scintillator strip. The goal of this research is to choose the best plastic scintillator type, length and cross-section for the full scale TB-J-PET scanner construction.

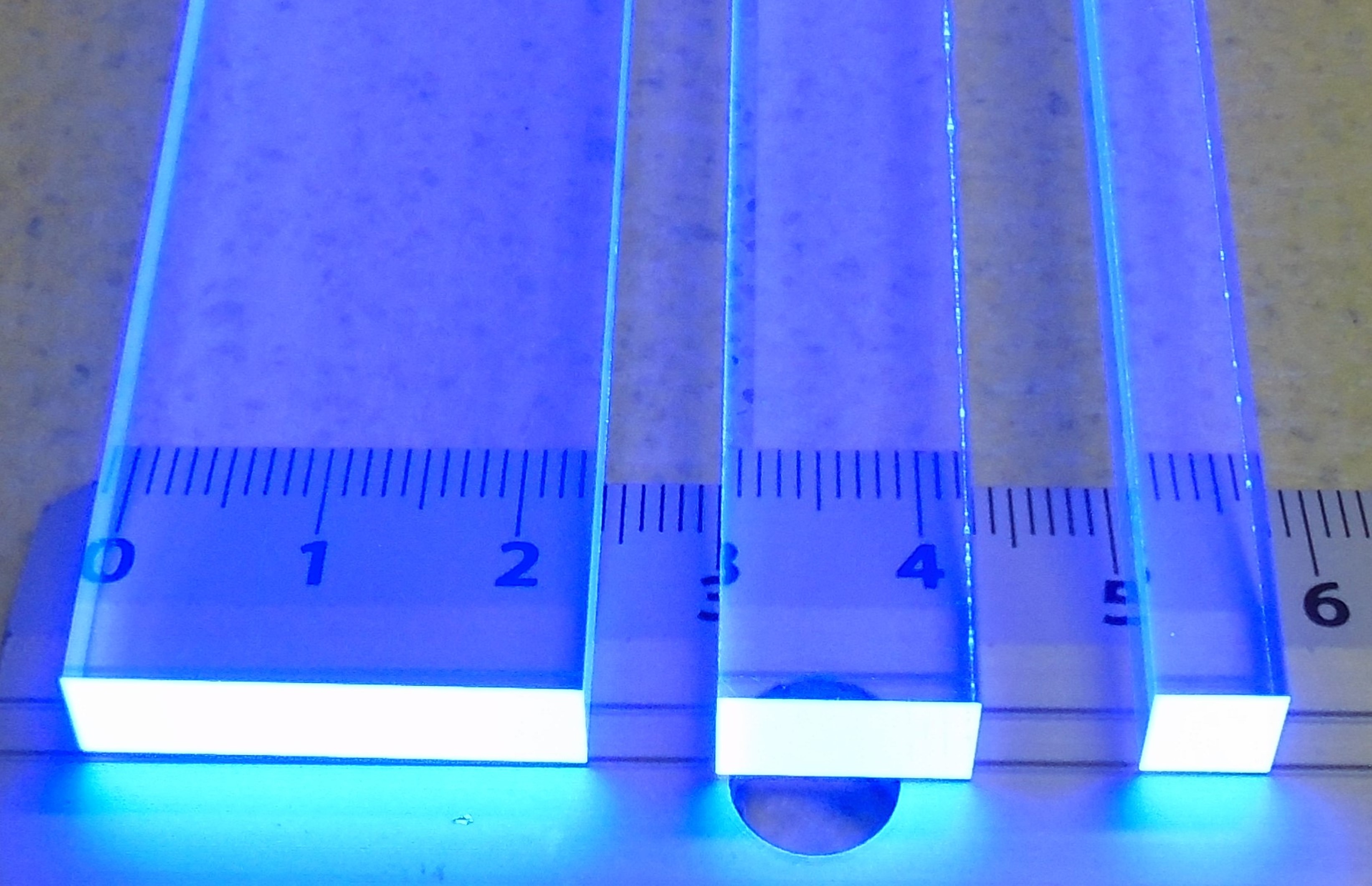

Left: Three EJ-200 plastic scintillators with cross-sections 6 mm x 24 mm, 6 mm x 12 mm and 6 mm x 6 mm under UV lamp. Right: Example of light attenuation in blue-emitting commercial plastic scintillators with dimensions 6 mm x 24 mm x 1000 mm which according manufacturers possess similar or the same properties. Transparency of the scintillation materials differs significantly.

In the Plastic Scintillators Laboratory we conduct research and development in the following areas:

-

developing new chemical formulations to improve properties of plastic scintillators;

-

synthesizing fluorescent dyes with short decay time and high quantum yield of fluorescence;

-

developing scintillators containing compounds with high cross-section for neutron detection;

-

researching scientific concepts from materials science, optics, lasers and OLED devices for application in scintillation detectors;

-

measuring properties of plastic scintillators: light output, rise and decay times, emission spectra, technical light attenuation length;

-

testing and verifying properties of commercial plastic scintillators for the total-body J-PET application;

-

assembling plastic scintillators with silicon photomultipliers and light reflectors to manufacture time-of-flight gamma radiation detectors;

-

investigating plastic scintillators produced with the use of new methods like additive manufacturing 3D printing;

-

tuning of plastic scintillators to increase radiation hardness in plastic scintillation dosimetry application.

More information can be found in:

- Investigation of the light output of 3D-printed plastic scintillators for dosimetry applications;

- Blue-emitting polystyrene scintillators for plastic scintillation dosimetry;

- Technical attenuation length measurement of plastic scintillator strips for the total-body J-PET scanner;

- Synthesis and characterization of plastic scintillators for the total-body J-PET scanner;

- Novel scintillating material 2-(4-styrylphenyl)benzoxazole for the fully digital and MRI compatible J-PET tomograph based on plastic scintillators;

- PALS investigations of free volumes thermal expansion of J-PET plastic scintillator synthesized in polystyrene matrix;

- Plastic scintillators for positron emission tomography obtained by the bulk polymerization method.